Dust Collection should vent outside Posted on September 29, 2024 by Dave Fowler

Wood dust is a known carcinogen, can cause serious respiratory issues, and is an especially difficult problem for small shops:

OSHA testing shows most small shops vent their dust collection systems inside which builds such dangerously high dust levels that most small shop woodworkers get more fine dust exposure in a few hours than large facility workers get in months of full-time work ~ Bill Pentz

I've gone down some huge rabbit holes while figuring out what to do about dust collection in my own shop. For such a simple sounding problem the solutions are surprisingly immature. No one can agree on standard ducting sizes, much less a standard system for adaptors. There are essentially no testing standards for the machines and no regulating body for the hobbyist market, to validate that what's advertised is true - resulting in it usually not being so.

But what I find the most frustrating, is the heavy focus on in-shop air filtration systems, and the lack of awareness or even options on externally venting the dust.

The problems with the popular systems are many:

- the tests are non-standard and unregulated (and prove to be untrustworthy)

- the machines are incredibly noisy

- they take up a ton of space

- they're expensive, especially the bags and filters that need to be changed regularly

The unsung solution is simple: vent the fine dust outside

and potentially even put the whole machine outside, which would make your shop not just less dusty but also much quieter.

Obstacles to external venting

The main obstacles here are a few

1. Too Noisy for Neighbors

If your shop is in a densely populated area these machines running outside (which can get up to 90-100 decibels) will drive your neighbors nuts. You could put some sound baffles around it, but that's a lot of work.

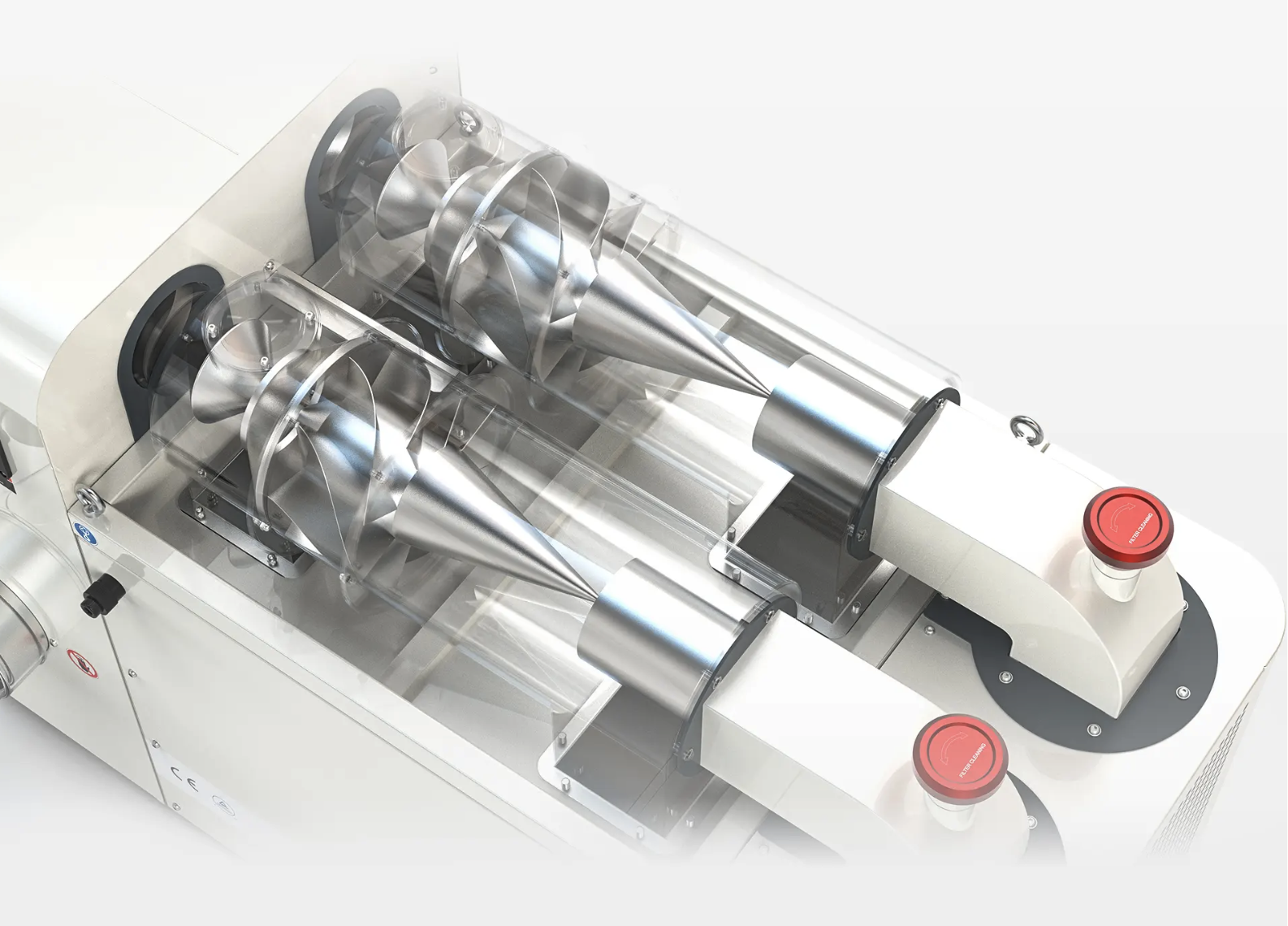

Solution - the solution here is Centrifugal style dust collectors. I recently got the Harvey Gyro G700 and it sounds very similar to an air conditioning unit. It's always under 70 decibels, just a bit above the range for those external AC units.

It's incredibly powerful, incredibly quiet, and beautifully designed - I love it.

2. Unclear dust ventalation rules in your city

The rules around external ventilation are all local building codes - meaning they really depend on where you live - meaning there's no common or easy answer.

Solution - cities need to be clearer with these rules and shop owners need to publish and share what they find as they work with their local building departments.

3. Temperature control

A good dust collector will cycle the full volume of air in your shop in just a few minutes - not ideal for your temperature control bill. Many shops operate with the windows and doors open and this won't be a problem. But for shops in less temperate climates, it's a non-starter.

Solution - venting external as an option. Dust extractors should be built with an extra exhaust and the option to bypass the finer filter controls and vent directly outside. This would greatly reduce noise, the cost of filters, while removing the problem of small particles being circulated in your shop.

Shop owners could then make their own trade offs of exhausting internally when they need to keep the temperature in control.

The ideal dust collector

If I were in the dust collector market I'd design one like this:

- Centrifugal style - as it's quiet, powerful, efficient and isn't much larger than the ducting itself

- Exhausts (and is possibly installed) outside - less shop noise, less/no fine filters, and no chance of fine dust getting recirculated

- Optionally exhausts internally - when it's important to maintain a temperature in the shop. It'd have to be easy to switch between the two.

- Wall or roof mounted - with a shoot to go down into a collection bin. There's no reason a centrifugal machine needs to take up much floor space. The more it can be blended into common duct work the better.