Things I Learned About Woorkshop Dust Collection Posted on October 11, 2024 by Dave Fowler

Dust collection might seem like a simple part of setting up a woodworking shop, but I've discovered that it's a lot less standardized, regulated, and clear than you might imagine. Here are some key lessons I've learned about dust collection:

1. Fine Dust is Dangerous

One of the first things I learned was that fine wood dust is much more harmful than most people realize. Bill Pentz, a professor who became a champion of small-shop dust collection, suffered a severe respiratory illness even after installing what was supposed to be a top-rated dust collector. He highlights how dangerous fine, invisible dust can be—especially in small shops where dust collection systems often aren’t as robust as those in commercial facilities.

Most small shop collectors don’t handle fine dust effectively, meaning woodworkers can be exposed to dangerous levels of dust in just a few hours.

> most small shop woodworkers get more fine dust exposure in a few hours than large facility workers get in months of full-time work - Bill Pentz

2. Cyclones Are Essential

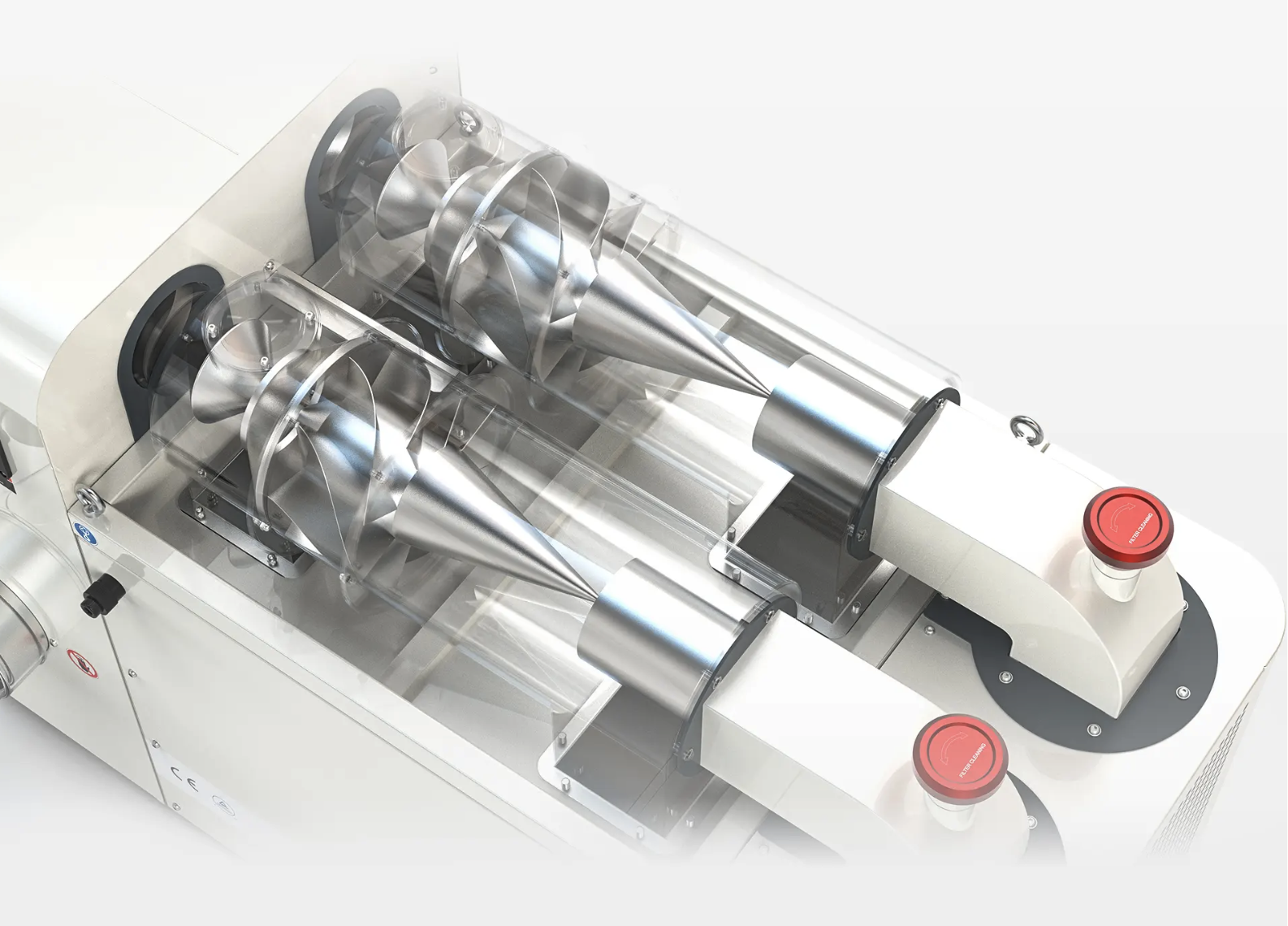

Dust collectors that use cyclones separate out the larger wood chips and particles before the air goes through the filter, which dramatically extends the life of your filters. Without a separator, dust quickly clogs filters, which means frequent cleaning and reduced airflow. The Harvey Gyro Air G700 is a great example of a system that uses advanced cyclone technology to keep your filters cleaner longer while maintaining excellent performance. It’s also one of the quietest dust collectors I’ve seen—perfect for a home shop.

3. Shop Vacs are for velocity, Dust Extractors for Volume

If you’re thinking of using one large dust collector for all your tools, be careful with how you handle air restrictions. It might seem logical to connect a 4-inch dust collector hose to smaller tools like sanders, but doing so can drastically restrict airflow and possibly even damage your equipment due. Dust extractors are more expensive and powerful than shop vacs, but for many jobs a shop vac is superior.

For small tools like sanders, a good shop vac with a proper filter is usually the better choice. To cut expensive bags and filters you may want to use a cyclone separator with your shop vac to keep it running smoothly and extend its life. The Wood Whisperer offers great insight into this setup.

4. Vent Outside Whenever Possible

Venting dust outside is the gold standard for fine dust collection, as it completely removes dust from your shop. However, local regulations often prohibit it, and there can be concerns about temperature control in climates where heating or cooling the shop is important. That said, if you're in a temperate climate like California, where I am, venting outside is a no-brainer and has the added benefit of improving overall airflow.

5. Noise Matters – Dust Collectors Are the Loudest Tool in the Shop

One of the biggest surprises in my dust collection research was how incredibly loud these systems can be. Dust collectors are often the loudest machines in the shop, even louder than table saws or planers, with some units reaching over 100 decibels—comparable to the noise of a motorcycle or jackhammer. That’s not just annoying, it can cause serious hearing damage if you’re not wearing proper hearing protection. To mitigate this, you can use insulated ducting or build homemade mufflers to dampen the noise.

6. The Future is Centrifugal

Speaking of noise reduction, the Harvey Gyro Air G700 has shown how far centrifugal extraction can take dust collection. Unlike traditional systems, centrifugal extractors use a different mechanism to separate dust, and they do it quietly. The Gyro Air is not just effective at capturing dust—it’s also incredibly quiet, making it ideal for home workshops. I love it. It runs at around 70 decibels, which is comparable to an air conditioner and much more manageable than older dust collection systems.

I swear this isn't an ad for Harvey, but the Gyro Air is just so good.

7. Marketing Claims Are Not Verified—And Are Usually False

The dust collection industry is notorious for inflated marketing claims, particularly when it comes to airflow (CFM) and horsepower ratings. Most of these claims are not verified—and are usually false. For example, many shop vacs advertise "6 horsepower," but no small vacuum can realistically deliver that kind of power. Trustworthy brands like Jet and Powermatic have more accurate ratings, but in general, it’s best to focus on performance data from independent testing, not the specs printed on the box. Bill Pentz provides detailed information on how to navigate these misleading claims.

8. Start with a Hose and Magnets

I started my shop (and still just use) one long hose on the dust collector with magnetic adapters. I've been happy with these from Magport, and have also enjoyed following Izzy Swan's Quick Lox. It takes me just 5 seconds to swap the dust collection between tools (about the same amount of time as opening and closing ports in ducting) and allows me to be much more flexible with my tool layout. I’m still not fully settled into my perfect layout, and having the ability to quickly move the hose around has been invaluable. One day, I might install some permanent ducting, but for now, the hose works great, and it keeps things simple and cost-effective.

Conclusion: Choose the Right System for Your Needs

Dust collection is not one-size-fits-all, and what works best for one shop might not be the right solution for another. For my setup, using a cyclone-based dust collector, venting outside when possible, and adding a flexible magnetic port system has proven to be the most effective solution. I also recommend fine dust filters and a combination of shop vacs with cyclone separators for small tools. It’s an investment in both your shop’s cleanliness and your long-term health.

By taking these steps, I’ve been able to create a dust collection system that keeps my shop clean, protects my lungs, and doesn’t interrupt my workflow. Whether you're setting up a new shop or upgrading an existing one, I hope these insights help you on your journey.

Let me know your thoughts or if you have any questions!